Product Destription

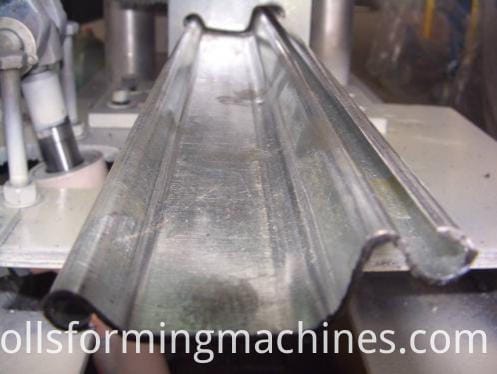

The Roller Steel Shutter Door Roll Forming Machine can manufacture the galvanized roller shutter door slat. Produced products are in fashionable design and are widely used.Roll Shutter Door Slat Roll Forming Machine with the highest security in rolling fire doors, rolling steel doors, fire doors, rolling shutter, offshore rolling doors, offshore rolling fire doors, storm doors.

Quickly information:

1.Control system:computer control

2.Main forming unit driving motor power:5.5kw

3.Material of rollers:45#steel,quenched HRC58-62,coated with rigid chrome.

4.Material of roller shafts:45#steel

5.Step of rollers:14steps

6.Forming speed:10-15m/min

7.Thickness to be rolled:0.5-1.5mm

Components of Line

1. Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

a. Coil inner diameter: 450-550mm

b. Coil max width: 300mm

c. Max carrying capacity: 3000kg

(you can choose this part with Electric or hydraulic)

2. Entry leveling and punching dots

This part will level coil to make sure it is neat clean and straight.

3. Roll forming machine

a. Number of forming steps: 14 stations

b. Shaft material: 45# steel with quenched treatment, precision machined,

The diameter: ¢56mm

c. Roller material: bearing steel with quenched treatment

d. Transport: by gear

e. Forming speed: 10-15m/min

f. Motor:5.5kw

g.Voltage:380v, 50Hz,3 phase

h. Structure: independent stand

4. Shearing system

The material of blade: Cr12Mov, Hardening HRC 58-62℃

Length Tolerance:3m±1.5mm

5. Hydraulic station

Hydraulic motor Power: 3kw

Hydraulic oil: 46#

Hydraulic pressure : 12Mpa

6. PLC station

PLC control system, we will take Panasonic or you can specify the one you like. Different with normal machine, PLC programmed will add servo cutting saw control parameters.

7. Run out table

It adopts welded steel and supported roller to transmit the products.

1.Processing flow diagram of machine

Manual Decoiler→ Feeding material into machine →Roll forming machine →Measure length →Punch the lock holes→Hydraulic cutting →Finished Products

2. Technical parameters

| Material | Raw material | Galvanized |

| Thickness | 0.8mm |

| Manual decoiler | Inner Diameter:450-550mm | Expand by manual |

| Outer Diameter: max 1500mm |

| Max Coil width:300mm |

| Capacity: 1.5T |

| Main Forming machine | Forming steps | 12 rollers |

| Shaft diameter | 50mm |

| Design type | Middle plate |

| Machine frame | Memorial arch |

| roller material | GCr12MoV steel |

| shaft material | 45# steel with tempering |

| Work speed | 0-12m/min |

| Transport | By gear |

| Power of main machine | 5.5kw |

| Type of cutting | Hydraulic |

| Cutting tolerance | ±1mm |

| Cutter | Gcr12 |

| Punch mould | Gcr12 |

| Working pressure | 20MPA |

| Hydraulic system | Hydraulic oil | 46# |

| Hydraulic power | 4kw |

| Cutting length | As required |

| No distorting or wasting. High level safety factor. |

| Control Device | control | By PLC |

| PLC language | English and Chinese (or as required) |

| Touch screen | Delta |

| Function | Automatic length and quantity measurement |

| Other Spare part | Weight | About 3.8 ton |

| Dimension | 5200*800*1400 (mm) L x W x H |

| Main body color | Main body color |

| Voltage | 380v/50hz/3ph(or as required) |

| | | | |

Looking for ideal Roller Steel Door Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Steel Shutter Door Forming Machine are quality guaranteed. We are China Origin Factory of Roller Steel Shutter Door Roll Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Roller Shutter Door Forming Machine

Mr. Cary xu

Mr. Cary xu