double line light keel Roll Forming Machine has two sets of rollers,they can produce two keels. If the dimension issuitable , our technicians can simplify the two rollers into one. Combined machines can help you to save space and raise productivity. To our great joy,we have already developed three lines.

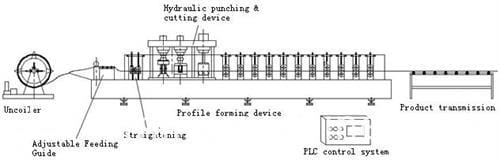

Processing flow diagram of machine

Manual Decoiler→Feeding material into machine →Roll forming machine →Measure length →Hydraulic cutting →Finished Products

decoiler

inner Diameter 450-550mm

Outer Diameter max 1500mm

Max Coil width 500mm

Capacity 3T

main forming machine

Forming steps 12 rollers

Design type Guide column

Machine frame Memorial arch

Changing size methods Completely changing the mold linear system

Structure independent stand

Power of main machine 7.5 kw

Type of cutting and punching Hydraulic

Hydraulic servo tracking cutting

the machine is with servo tracking cutting, the cutting knife can move automaticly. so that, the tracking cutting can keep same speed with the main forming machine, and cut the finished products continually .

| No. | Name | Size and mode | number | note |

| 1 | base frame | 100*100*6 | 1 | |

| 2 | Control station | | 1 | Include switch button |

| 3 | Hydraulic station | 4kw | 1 | |

| 4 | Oil pump | 63*80*80 | 1 | |

| 5 | Cooling device | 35Hz | 1 | |

| 6 | Sensor | Npu | 2 | |

| 7 | Encoder | 600 | 1 | Omron |

| 8 | tachometric wheel | | 2 | |

| 9 | Servo motor | 3.9kw | 1 | GSK |

| 10 | Mold | Mulfan1 | 4 | |

| 11 | Lead screw | Sfu4020-1230 | 1 | Taiwan |

| 12 | Guide | HG35-2000 | 2 | |

| 13 | Slider | HGH35cA | 4 | |

| 14 | Coupling | | 4 | |

Shearing Machine:

Material of blades: Gcr12 quenched

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Electic Control System:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

additions

Sometimes there are some embossing and holes on our customers samples. For the holes, a punching device must be added. For embossing ,we usually put the embossing model on the former rollers .If you want your logo to be printed an the keel,we have two methods.One ,the same as getting holes ,add a logo punching system in front of the hydraulic station.Or we make some changes on the rollers.Then you can get your logo while roll forming.

Looking for ideal Light Keel Roll Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Stud and Track Roll Forming Machine are quality guaranteed. We are China Origin Factory of C U Omega Shape Former. If you have any question, please feel free to contact us.

Product Categories : C/U/ Channel & T Bar Roll Forming Machine > Drywall Profile Roll Forming Machine

Mr. Cary xu

Mr. Cary xu